We love Jeremy- Rest in Peace. Jeremy’s the best. Our team always looks forward to competition, one of the reasons –

to make Jeremy proud of us. His opinion was so important to my team and he motivated them just by looking at our ROV.

Goggle Frogs

Marine Advanced Technology Education

Competition 2014

Home Schooled/ North Star Academy

Redwood City, CA

SCOUT Class

Aptos High School, CA

Team:

E. G.-Advisor- “Start from scratch”

M. Y. -Designer- “Don’t overestimate your performance.”

C. G. -Pilot- “You can do better on your next try.”

T. P. -CEO-

S.W. CFO- “Sometimes technology fails.”

S. W. is in 4th grade. He is a very good spotter and thoroughly enjoys learning about robotics. Sam attends North Star Academy and is the CFO (Chief Financial Officer) for the team. This is his first year in a MATE competition.

E. G. is in 8th grade and attends North Star Academy. She is the team’s advisor due to her experience with ROVs; she has participated in the MATE competition for the past two years. Unfortunately, she is not able to attend this year’s competition.

C. G. is in 5th grade and attends North Star Academy. He switches between tethering and driving the ROV. He has also participated in the MATE competition for the past two years.

M. Y. is in 8th grade and attends North Star Academy. He switches between tethering and driving the ROV. This is his first year on a ROV robotics team.

T. P. in 3rd grade. He is the CEO (Chief Executive Officer) and also directs the viewfinder. This is his first year in a MATE competition.

Coaches:

Mira Gillet

Charles Gillet

ABSTRACT

This design is the combination of 1 year of development. The first stage, the frame was too heavy, so we switched to a hamster cage, and the third stage was also a setback because the team insisted on a PVC cage, but this stage of the ROV we had the time and resources to use a better hamster cage and servo motor to develop the ROV. We also had the access to a pool that allowed us to test the ROV in actual conditions of water.

Budget (See attached)

COMPANY EVALUATION

The most rewarding part of this experience is learning about ROVs and their impact on the world’s oceans. Our group has learned about what an ROV does, what one is, and what it takes to create and control one. The company has learned the fact that ROVs are used in large amounts to survey shipwrecks and map the ocean floor. For example, the famous person, Robert Ballard, who found the Titanic’s wreck, was actually hired at first by the US military to locate the wrecks of several US nuclear military submarines in order to stop the Soviets from discovering the technology used in them. This shows the fact that ROVs are useful for not only finding old shipwrecks, but also modern shipwrecks and other things lost in the ocean. ROVs are also useful for their ability to locate and fix problems such as oil leaks or malfunctioning sensors on the ocean floor.

The greatest thing learned by the group from this experience is the fact that, even though people may fail, they are constantly learning and adapting to their situation by fixing the problems that are occurring. For example, the group had tried to put a scoop on the ROV, but after it was shown to cause problems with the ROV’s hydrodynamics, it was removed. Another example was when one of the two ROV pilots was discouraged, leading to someone else trying to pilot the ROV and showing that they were capable of piloting the robot.

Next time, the group will try to add a scoop to the ROV in a way that is not extremely rushed, so the robot is capable of picking up the designated objects much faster and easier than the claw can.

Design Rationale

The company at first attempted to use a bicycle brake in order to make a claw mechanism, however there was no cable for a bicycle brake that was long enough to function.

At first, we had motors that were functional, however when we needed more thrust on the ROV, the person who went to the store was informed that the motors that were being used were actually adapted and were not the motors that were being purchased. The motors that were then purchased were brought to a hobby shop to make the motors work, as well as the claw. A person (A) at the line in front of the person (B) trying to make the claw work told them that they should use a servo, which the person (B) standing in line promptly pretended to have extensive knowledge about. This person (B) then, rather than asking the question of “How can I make this claw work”, said, “I would like to buy a servo”, though they did not know exactly what that was. The result was a new claw design that involved the servomotor, which is a motor that uses a current to hold the machine in place. This new claw could open and close on command, and therefore was far more useful than previously thought.

Stage 1: The frame was too heavy, so we learned to come back next year with a lighter frame.

Stage 2: We switched to a hamster cage due to the first year’s setback, but propellers got caught in the motor because they were not protected.

Stage 3: This year we had the time and resources to use the hamster cage properly, to use a servomotor for the claw, protection for the engines, and to use more of the adapted engines, in order to develop the ROV.

Stage 4: We went to the competition practice, and we realized that a scoop could be beneficial to the ROV’s performance, as it could score 30 points at once. This taught the team that next year we should go for the easier points first. When the group decided to add a scoop to the ROV, it was made obvious that the new design was not very hydrodynamic due to the fact that we had added a dustpan with a net instead of a bottom piece, and this was causing massive amounts of drag on the frame of the ROV. This also resulted in the reduction of efficiency of the claw, and therefore the team decided to remove the scoop.

Technical and scientific concepts

The wiring workshop taught our members how to solder and how the resistors work. The workshop also allowed for us to learn how fuses work and taught us the reason to use the fuses and other materials provided. We also learned what single pull-single throw switches and double pull double throw switches were, and this allowed us to use these properly as well. This was the point at which the mentors were changed into regular team members, as the younger children were not able to fully comprehend the concept of the more complicated switches.

Physics- heavy frame to lighter frame.

The team decided to try installing larger propellers, and was wondering if this would take up all of our voltage. However, we did not have enough time and wish to test this feature next year.

Troubleshooting Technique

The Troubleshooting Technique we used was trial and error.

We were going to replace a propeller with a larger one temporarily in order to solve the problem of a lack of thrust in the ROV, and then multiply the required voltage by 4 in order to learn if this would stay within the required amount of voltage for the ROV, but due to some setbacks and a lack of time to work on this, the replacement propeller was not installed.

Troubleshooting Explanation

The Failed Scoop

Our group at first had just a single grabbing arm, which would be used for all purposes (And it continues to have just one grabbing arm), however, we felt that it was necessary to add a scoop to the ROV in order to complete the challenges faster. In the beginning, we attached a dustpan with holes drilled into the bottom in order to make the robot have the capability of picking up entire loads of PVC pipes while also remaining hydrodynamic. This made the ROV, however, far less hydrodynamic and the team decided to fix that problem. Two team members removed the bottom of the dustpan and replaced it with a net, in order to make sure the dustpan was hydrodynamic. This also was to make sure the dustpan was capable of holding the PVC pipes without them rolling out. Sadly, the dustpan performed poorly in tests, and also was proven to make the grabbing arm of the ROV far less effective, as the dustpan scoop was meant to hinge and scoop up PVC’s using the same servo motor as the claw. Even without these two drawbacks, the dustpan even had the side effect of a severe reduction in the stability of the ROV underwater, causing massive problems with its hydrodynamics. After such obvious problems with the usage of a dustpan like this, we simply decided to remove it.

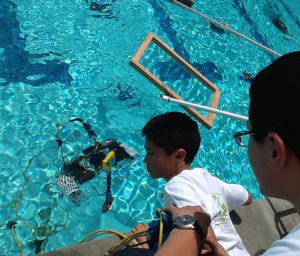

The group also created a sort of viewing device that was meant to place a slightly submerged pane of glass underwater in a wooden frame. This device is useful to the group due to its ability to allow the group members to see through a flat surface into the water. The glass pane negates the waves of the water, allowing the group to see straight into the water without any distortion, and therefore allow the ROV to function at a much higher efficiency.

At one point during a practice run, a group member was discouraged with the controlling of the ROV to attempt to complete a mission task. This resulted in a different person in the group operating the ROV to pick up the PVC pipes provided.

We had setbacks, but the determination of the team allowed us to complete the project. There was an instance of the “Cycle” button on the servo being confused for a “Power” button, and this caused setbacks because of the fact that the servo was then going crazy and making the claw rapidly open and close without input.

The adult was justified in getting the supplies for the practice. Most of the people at the teams on the competition had extra time for this, but we had to completely come up with our supplies on our own, and are doing this on the weekend. Therefore, the adult needs to find the correct materials, as we only have 5 people on the team.

Safety section and Philosophy

Though our company did not use safety goggles in many of the images, these were created for the sole purpose of making the project seem more impressive, and safety equipment was indeed used outside of the recordings and pictures shown. Our company understands the concerns of the judges over safety, and assures them that the company has the safety of its workers in the highest priority. Adults and coaches made sure there were no short circuits or exposed wires that could shock the workers during construction, and adult supervision has always been present in the construction of the ROV

Safety of the ROV itself

The ROV contains a fuse to stop a current from causing any problems. It also has covers on the propeller in order to protect anyone near the vehicle as well as the vehicle itself from foreign objects.

Challenges

Our workers have learned many things over the work we have done. Charlie learned while we are putting protectors over the motors, that the motors are indeed delicate and not to be smashed on the ground after new propellers were installed over a long period of time. However, this mistake and near catastrophic failure led to a new idea of putting the covers over the motors in a different way, where they were cupped over one side of the motor instead of completely surrounding it. This taught the entire group that even the worst mistakes can lead to better results.

One attempt to improve the rover later on will be to install newer propellers. After the first propeller was broken, the team decided to try installing larger propellers, and was wondering if this would take up all of our voltage. However, we did not have enough time and wish to test this feature next year.

Challenge faced and the method(s) used to overcome it

At first, the company had the problem of the servo motor, for some reason, the servo was going psycho. However, we learned through observation that the servo was only going crazy due to a mistaken button of “Cycle”, which we thought was the on/off switch button for the servo itself.

Accomplished the missions

We accomplished the creation of a successful claw that took nearly a month to create. Our determination paid off in the construction of the claw, as we now had a new claw that could retrieve pieces faster.

Another accomplishment is the fact that, instead of the modern idea of presenting fake and irrational problems to children, we are giving real world problems and work to these children to learn.

Company Brainstorm

A student at our school has a father who was interviewed on CNN about his work on satellites in the case of the missing Malaysia airlines plane. The case of the missing airliner is currently being worked on by ROV crews in real life, which shows how we

Has this ever happened to you? Monitoring a radar screen in a control tower when the airline you are tracking suddenly vanishes? Have a missing plane with hundreds of people on board? Goggle Frogs can help! With our ROV technology, we can locate that plane with ease! So the next time you lose your multi-million dollar airliner, we are there to help! Call 1-800-___-____ today! (Tell us where it is first)

Lessons learned: Good design changes come from mistakes and how servo motors work.

Servo Motors: Servo Motors are rotary actuators that allow precise control of angular positions. It is made of a motor coupled to a sensor for position feedback. It also has a relatively sophisticated controller. They use a Servo Mechanism to create closed loop control with a generic open loop motor.

Future Improvements: Moving to Navigator

Which is 6th through 8th grade and 3 people on our team will be 6th grade and higher.

Reflections: This project is definitely worth doing because we learned a lot. We will be back next year. The person at the hobby shop warned us that the products we were buying were never designed to be used like that, and the fact that were are using these products in an unconventional way proves that the people who only use products in the conventional way are not creative, and also proves that since we took the risk of using a product in a way that it was not supposed to be used, we are creative.

Teamwork:

At first, Michael and Eva started off as mentors, but became team members when the younger members of the team had difficulty in describing details of the ROV and constructing it.

References:

Materover.org to research the requirements of Scout rover

http://en.wikipedia.org/wiki/Servomotor

http://wiki.answers.com/Q/What_is_the_difference_between_a_fuse_and_a_circuit_breakers

Acknowledgements: MATE competition,

Thank you to: Kim Swan, who is always on the phone

Jeremy at MateROV, who helped us with our measurements

Steve Batsford, who came up with the adaptive motor design.

Other Jeremy, who invited us to the competition.

Laurel’s hobby shop in San Carlos, for giving us options on servos to choose from, one of which was already waterproofed.

The future health of the ocean is threatened by the constant shipwrecks, and therefore oil spills and garbage spills, in the middle of the ocean. Often, garbage is dumped into the ocean to save space in landfills, and this creates entire ocean currents full of plastic. This can be helped, at least in small amounts, by the usage of ROVs or ships to clean up wrecks and oil spills in the ocean, and possibly remove some trash from the ocean as well. Observing the ocean floor can contribute greatly to science and overall technology involving the ocean, as these experiments and observations allow people to think of new ways to solve problems underwater. Data collected from the ocean floor can also contribute to the collection of resources, such as oil, from the ocean rather than from land. At the same time, the information collected from the ocean floor allows people to understand how life develops in the deep ocean, and also shows people how the interference of humans can cause problems with the ecosystems through garbage and oil spills in the oceans. Overall, the usage of ROVs allows people to understand their impact on the world, and permits scientific research to be advanced further using data from the vast bodies of water that are called oceans.